Posts by Houston Dynamic

Machine Alignment is Essential to Proactive Maintenance

According to the Department of Commerce, there about 12.4 million electric motors in use in industrial operations across the United States that operate at 1hp and above. Approximately 25% of these motors will fail in the coming year. Machine alignment can help those motors run more efficiently, which saves costs in energy consumption and reduces…

Read MoreCan Effective Preventive Maintenance Scheduling Reduce Downtime?

Industries often operate 24 hours per day to maximize production, which causes them to push machines to their limits. The rate of machine part failure is also increasing as a result. Demand has increased for preventive maintenance (PM), but it requires complex coordination with production, maintenance, and management departments. Below we will discuss the separation…

Read MoreProactive Versus Reactive Maintenance

Many organizations are realizing the benefits of embracing a proactive maintenance approach. Others still rely heavily on a reactive maintenance strategy, or wait for problems to arise before dealing with them. This ultimately leads to reduced asset insight, improper planning, time delays, unexpected costs, and a resulting inefficient maintenance plan. It is important to find…

Read More6 Steps to Optimize Maintenance Practices

Plant owners across the globe are aware Lean maintenance practices can improve production, minimize downtime, and reduce costs. Unfortunately, as much as 90% of performed maintenance in the United States is done reactively, instead of proactively. Reasons for this include aging equipment, scarcity of spare parts, and the increasingly higher demand in manufacturing speed. We…

Read MoreTips For Improvement in Maintenance Programs

Asset utilization, equipment capacity, and overall equipment effectiveness (OEE) are the responsibility of many departments, as well as the entire organization. It focuses on developing your assets to produce the greatest possible capacity. This is achieved through performance efficiency, measuring and managing availability, and the rate of quality. Plants that truly want to maximize their…

Read More4 Maintenance Tips to Extend Equipment Life and ROI

Heavy machinery, especially in oil and gas, mining, farming, or other industrial applications, requires regular maintenance to ensure they continue working reliably. When large machinery is poorly maintained, it not only runs inefficiently, but is also more likely to breakdown and cost you thousands – not to mention that faulty equipment can pose a serious…

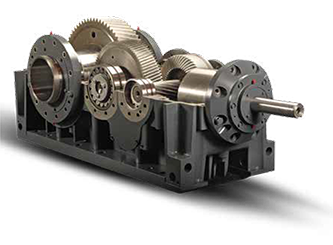

Read MoreDo I Need an Authorized Rexnord Service Center?

When faced with the choice of repairing or replacing critical equipment containing Rexnord components, many plant maintenance professionals ask the question: do I need an authorized Rexnord service center? Rexnord is a manufacturer of engineered mechanical components including gears, drives, gear boxes, couplings, and bearings for a wide variety of industries. With the performance of…

Read MoreEquipment Series – Wind Turbines

In the next installment of our Equipment Series, we will focus on wind turbines. A wind turbine uses the natural movement of air to spin the turbine and create energy. They are manufactured in a wide range of vertical and horizontal axis turbines. The smallest wind turbines can be used to charge batteries or as…

Read MoreEquipment Series – Steam Turbines

The next installment of our Equipment Series focuses on steam turbines. A steam turbine is a type of generator that extracts energy from pressurized steam and applies it for mechanical work with the use of a rotating output shaft. It is often used as the drive in electrical generators. In fact, most of the electricity…

Read MoreEquipment Series – Centrifuges

The next installment of our Equipment Series focuses on centrifuges. Centrifuges are equipment that separate suspended solids from liquids using centrifugal (or circular) forces generated by a spinning internal mechanism. They use the principle of sedimentation to cause denser substances to move outward in a radial direction. At the same time, the spinning causes less…

Read More