- All

- Alignment

- Asset Management

- Careers

- Centrifuges

- Compressor Repair

- Condition Based Maintenance

- Diffuser Repair

- Equipment Maintenance

- Events

- Fan Repair

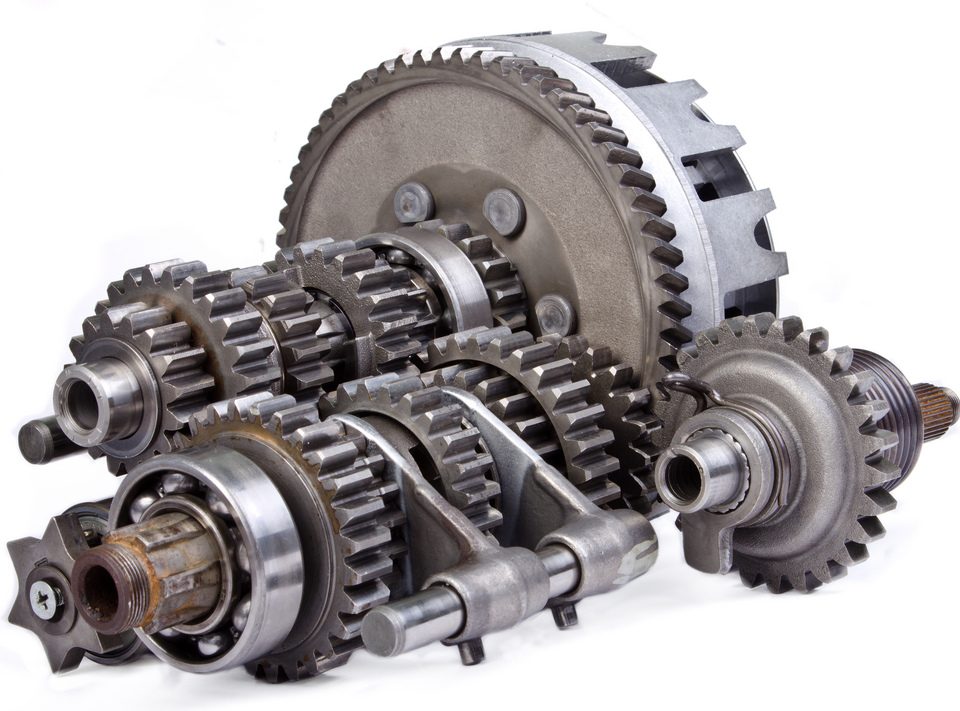

- Gear Box Repair

- Gearbox Repair

- Machining

- Motors

- News

- Oil & Lubrication

- Predictive Maintenance

- Preventive Maintenance

- Proactive Maintenance

- Pump Reliability

- Pump Repair

- Reliability & Maintenance

- Rexnord Service Center

- Root Cause Analysis

- Rotary Valves

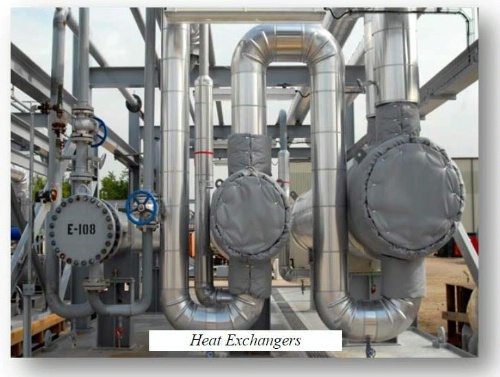

- Rotating Equipment

- Rotating Equipment Repair

- Seal Strips

- Sundyne Repairs

- Test Stand

- Turbine Repair

- Turbines

- Uncategorized

- Valve Repair

- Vibration