Equipment Maintenance

Extending Pump Life After a Rebuild: Best Practices for Maximum ROI

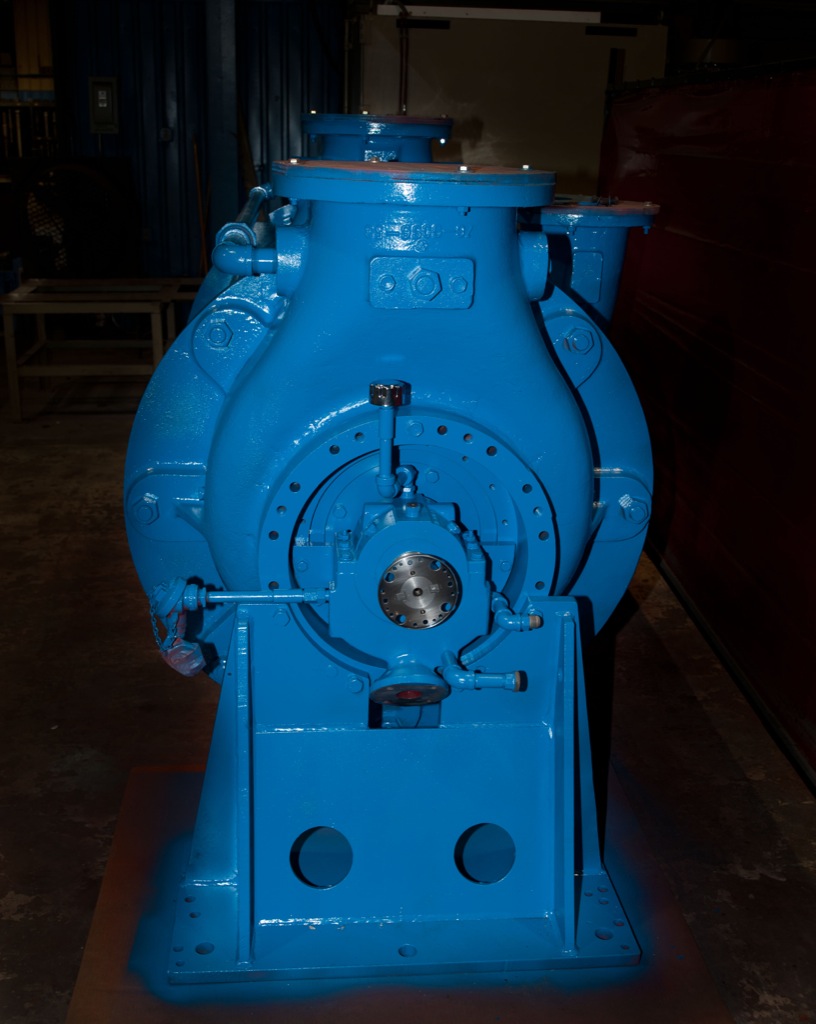

Industrial pumps are critical assets in most processing facilities, and their performance has a direct impact on reliability, safety, and operational costs. At Houston Dynamic Service, Inc. (HDS), we specialize in precision pump rebuilds that restore your equipment to like-new condition. However, even the most expertly rebuilt pump can fail prematurely if it’s not maintained…

Read MoreThe Evolution of Houston Dynamic Service

From Rock Bottom to Becoming the Largest Independent Rotating Equipment Repair Shop Like most companies in the fall of 2001, HDS was at rock bottom. Between Tropical Storm Allison, which caused extensive flooding and devastation throughout Houston, and the emotional and financial tragedy of the 9/11 terrorist attacks, HDS found itself on the verge of…

Read MoreMaximizing Operational Efficiency: The Case for Energy-Efficient Capital Equipment

As energy costs continue to rise, industrial companies are under increasing pressure to reduce their consumption and lower operational costs. Energy efficiency isn’t just a buzzword—it’s a critical factor in achieving sustainable operations, enhancing profitability, and complying with evolving regulations. For maintenance managers, engineers, plant managers, and other personnel overseeing capital equipment like industrial pumps,…

Read MoreStrategies to Reduce Cavitation in Centrifugal Pumps

The team at Houston Dynamic Supply have seen all sorts of issues with rotating equipment, including centrifugal pumps. One of the most common and devastating is cavitation. This happens when vapor bubbles form in low-pressure pockets and implode when entering into higher pressure areas. It leads to all sorts of damage on pump internals and…

Read MorePump Cavitation – What Causes it and How to Prevent it

Cavitation can occur in rotating equipment, especially centrifugal pumps. This cavitation can go unnoticed or diagnosed incorrectly. This can lead to issues with production, energy usage, output, lifespan of equipment, and even catastrophic breakdowns. To help with this, we will tell you all about pump cavitation – what causes it and how to prevent it.…

Read MoreShould you Upgrade or Replace Legacy Equipment?

The landscape of industry has changed a great deal, even over the past few years. New technology promises better outcomes that are worth the cost of new equipment. Your legacy equipment may be working just fine, even after its allotted usual lifespan. Or it may be showing signs of aging. But is the investment really…

Read MoreImprove Your Operation’s Performance with an R&M Assessment

Reliability & Maintenance (R&M) are generally assessments and audits that give scores on compliance goals along with recommendations for improvement. But these sort of assessments can’t be done in a day, week, or in some cases, a month. This is why we will show you how to improve your operations performance with an R&M assessment…

Read MoreStrategies to Optimize Condition Monitoring

Not too long ago the equipment you needed to monitor all of your assets was expensive and difficult to operate, especially from one location. As technology has advanced, all of that has changed to encompass your most important assets from onsite to remote. The cost to operate the monitoring equipment has also gone down, as…

Read MoreThe Importance of Oil Level Control in Equipment Performance

Precision lubrication means utilizing various data points and expert advice to choose the best lubricant, frequency, method, and volume needed to optimize performance and extend the lifespan of critical equipment. This is the goal of any maintenance program, and data is constantly changing. One thing that should be on your mind is the importance of…

Read MoreHow a Centrifuge Failure Almost Became Deadly

The team at Houston Dynamic Supply work with all sorts of centrifuges and rotating equipment across all industries. We have seen everything from catastrophic failure to simple fixes to rebuilding components at a fraction of the standard price. Below we will share a case study on a serious and nearly fatal failure of a centrifuge…

Read More