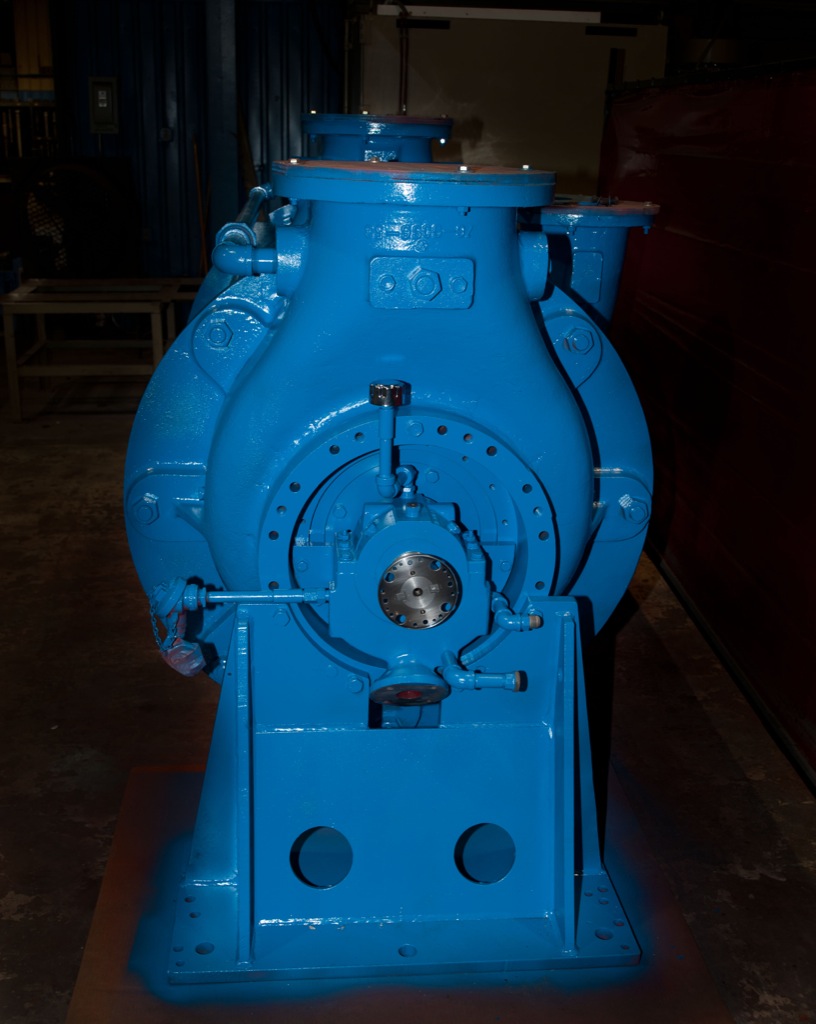

Pump Repair

Extending Pump Life After a Rebuild: Best Practices for Maximum ROI

Industrial pumps are critical assets in most processing facilities, and their performance has a direct impact on reliability, safety, and operational costs. At Houston Dynamic Service, Inc. (HDS), we specialize in precision pump rebuilds that restore your equipment to like-new condition. However, even the most expertly rebuilt pump can fail prematurely if it’s not maintained…

Read MoreStrategies to Reduce Cavitation in Centrifugal Pumps

The team at Houston Dynamic Supply have seen all sorts of issues with rotating equipment, including centrifugal pumps. One of the most common and devastating is cavitation. This happens when vapor bubbles form in low-pressure pockets and implode when entering into higher pressure areas. It leads to all sorts of damage on pump internals and…

Read MoreUpgrade Legacy Pumps With Modern Materials and the Latest Technology

New and legacy pumps are an essential part of many facilities such as water for municipalities, oil and gas, power generation, manufacturing, and many others. In the end, all pumps eventually succumb to wear, corrosion, and slowdowns or breakdowns. It is critical to have a plan in place for repairs and replacements, but there is…

Read MorePump Cavitation – What Causes it and How to Prevent it

Cavitation can occur in rotating equipment, especially centrifugal pumps. This cavitation can go unnoticed or diagnosed incorrectly. This can lead to issues with production, energy usage, output, lifespan of equipment, and even catastrophic breakdowns. To help with this, we will tell you all about pump cavitation – what causes it and how to prevent it.…

Read MoreHow Root Cause Analysis Can Improve Production Reliability

Approximately 20 to 30 % of all industrial maintenance hours are used for Root Cause Analysis, at times called RCA. Time was calculated by counting time used to find cause of problems, elimination, and any reports done at that time. It can also include anything from the time it takes to train operators in new…

Read More5 Top Ways Your Equipment Operators Can Improve Reliability

From experience we can tell you your critical equipment and operators are the most valuable assets in your organization. This includes everything from simple machines to the most complex and costly. Operators are the first line of defense and most likely to notice when something is amiss. Don’t waste this important human asset as there…

Read MoreTop Tips for Improving Pump Reliability

A large section of our industry can regularly use anywhere between a few hundred to several thousand pumps in their facilities. These pumps are connected to many other pieces of essential rotating equipment such as compressors, fans, blowers, turbines, and more. These organizations may have a yearly average budget of millions of dollars set aside…

Read More3 Ways to Improve the Performance of Your Vertical Pump

We at HDS are experts in all sorts of rotating equipment including vertical pumps used for a range of applications. However, it is important to keep them in optimal performance to improve efficiency and avoid unnecessary breakdowns. Below we will show you ways to improve the performance of your vertical pump. 1. Get a Health…

Read MoreThe Effects of Radial Thrust on Centrifugal Pumps

We are often asked about the reason why centrifugal pumps fail. Some say bearing or seal issues. Perhaps a broken shaft. However, in our experience, the common denominator in most centrifugal pump failures comes down to radial thrust in excess. As a result, below we will further discuss the effects of radial thrust on centrifugal…

Read MoreHouston Dynamic Now Offers Hydraulic Testing

HDS has over 40 years of experience in all types of rotating equipment repairs, including Sundyne pumps. In fact, repairing Sundyne pumps is a large portion of their buisness. As more and more Syndyne pumps came into the shop, General Manager Luke Lau said they encountered many customers who didn’t have the technical expertise to…

Read More