Preventive Maintenance

The Real Cost of Maintenance: Why Proactive Beats Reactive

When it comes to asset reliability and operational efficiency, maintenance strategy matters. While some organizations still default to a reactive approach—addressing equipment issues only when failure occurs—industry leaders are shifting toward a more proactive philosophy. Proactive maintenance prioritizes prevention, early detection, and strategic intervention, ultimately extending equipment life, improving safety, and reducing long-term costs. At…

Read MoreMaximize Equipment Reliability with Condition Monitoring

Your equipment was expensive to design, purchase, and install. This does not include the costs to operate, maintain, diagnose, repair, and ultimately replace. But did you know you can maximize equipment reliability with condition monitoring? We will show you how below. Do I Need Condition Monitoring? Depending on your operation, your rotating equipment could be…

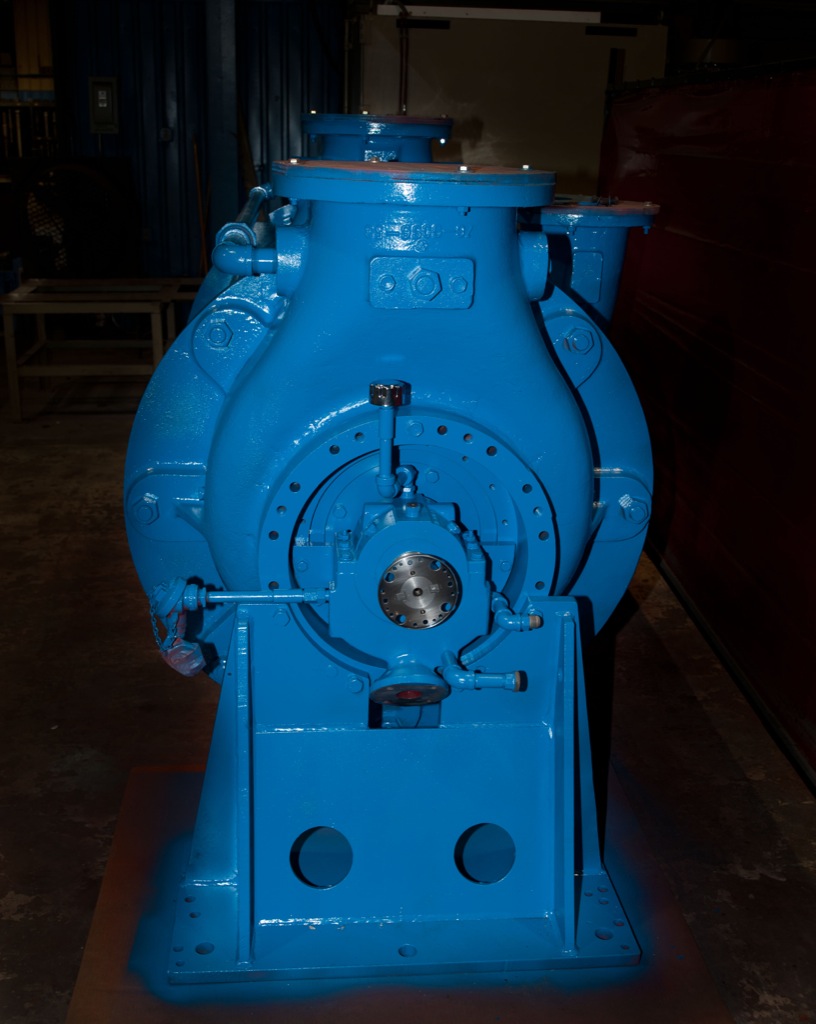

Read MoreStrategies to Reduce Cavitation in Centrifugal Pumps

The team at Houston Dynamic Supply have seen all sorts of issues with rotating equipment, including centrifugal pumps. One of the most common and devastating is cavitation. This happens when vapor bubbles form in low-pressure pockets and implode when entering into higher pressure areas. It leads to all sorts of damage on pump internals and…

Read MoreUpgrade Legacy Pumps With Modern Materials and the Latest Technology

New and legacy pumps are an essential part of many facilities such as water for municipalities, oil and gas, power generation, manufacturing, and many others. In the end, all pumps eventually succumb to wear, corrosion, and slowdowns or breakdowns. It is critical to have a plan in place for repairs and replacements, but there is…

Read MoreHow Vibration Analysis Optimizes Predictive Maintenance

Vibration analysis is one of the most powerful diagnostic tools to help you monitor, identify, and prevent a mechanical failure in your rotating equipment. It is also an essential component of any predictive maintenance because it can detect upcoming issues in machinery before they lead to catastrophic failures and expensive down time. How Does Vibration…

Read MoreImprove Your Operation’s Performance with an R&M Assessment

Reliability & Maintenance (R&M) are generally assessments and audits that give scores on compliance goals along with recommendations for improvement. But these sort of assessments can’t be done in a day, week, or in some cases, a month. This is why we will show you how to improve your operations performance with an R&M assessment…

Read More4 Steps to Set Up a Proactive Maintenance Plan

We’ve previously written about Proactive vs Reactive Maintenance – but there is more to say on the topic. It is one thing to know what proactive maintenance is. It is another thing entirely to implement it correctly in your organization. Here are four crucial steps to implement. Create a RAMS Team Reliability, availability, maintainability, and…

Read MoreHow to Implement Reliability Centered Maintenance (RCM)

We’ve previously written about Proactive Versus Reactive Maintenance and decided to build on that with a practice called Reliability Centered Maintenance. We will show you the steps and benefits to implementing it in your organization. What is Reliability Centered Maintenance (RCM)? RCM is the practice of focusing on the reliability of your equipment rather than…

Read More3 Top Strategies to Reduce Maintenance Costs

Below, we will show you how to leverage maintenance strategies to minimize the cost of running your facility. The Japanese Way The Japanese invented the concept of lean production that reexamines the way maintenance is done in a variety of operations. These practices include but are not limited to: Decrease the Request Response Time for…

Read MoreCan Effective Preventive Maintenance Scheduling Reduce Downtime?

Industries often operate 24 hours per day to maximize production, which causes them to push machines to their limits. The rate of machine part failure is also increasing as a result. Demand has increased for preventive maintenance (PM), but it requires complex coordination with production, maintenance, and management departments. Below we will discuss the separation…

Read More