Types of Machining Processes

Machining may be generally defined as the process of shaping down a piece of material into an intended design using specialty, power-driven tools. For example, many parts and components need some machining during manufacturing. Machining can be used to shape metals, plastic, rubbers, and more.…

Read More4 Steps to Set Up a Proactive Maintenance Plan

We’ve previously written about Proactive vs Reactive Maintenance – but there is more to say on the topic. It is one thing to know what proactive maintenance is. It is another thing entirely to implement it correctly in your organization. Here are four crucial steps…

Read MoreThe Importance of Root Cause Analysis

Root cause analysis, also known as RCA, is discovering the root cause of a problem in order to identify the correct solution. RCA also promotes systematically preventing and solving underlying issues rather than “putting out fires” as they form. Below, we will discuss the benefits…

Read MoreDon’t Let Soft Foot Compromise Your Equipment

Soft foot can be one of the leading issues encountered in rotating equipment. It is also known as machine frame distortion and is a complex condition that can result in damage to the equipment, along with its output. These include quality and mechanical problems such…

Read MoreIndustrial Centrifuge Maintenance

We previously discussed industrial centrifuge basics and wanted to continue by discussing industrial centrifuge maintenance. Like any other piece of equipment, proper maintenance is essential to keeping your centrifuge running optimally for as long as possible. The effort put into centrifuge maintenance pays for itself…

Read MoreIndustrial Centrifuge Basics

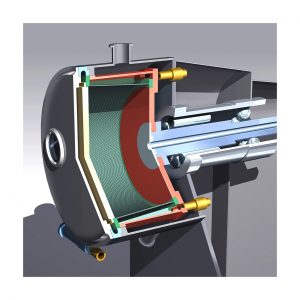

An industrial centrifuge is designed to use intense centrifugal force generated by mass rotation to meet the needs of various applications. They are generally used for large scale fluid separation applications. Think of an industrial centrifuge as a larger version of a lab centrifuge used…

Read MoreCentrifuge Repair Issues

Centrifuges are a key component to your assembly line and process. But what happens when they start to fail or break down completely? Know the signs to identify any centrifuge repair issues before they happen. Signs You Need Centrifuge Repair There are…

Read MoreCondition Based Maintenance Strategies Minimize Equipment Failure

We’ve previously discussed the benefits of developing an asset management strategy and thought we would continue in that frame of thought. FACT: A large number of equipment failures have nothing to do with the amount of time in service. FACT: Most equipment failures can be…

Read MoreDeveloping an Asset Management Strategy

We’ve previously discussed the benefits of Implementing A Reliability Centered Maintenance Program and thought we would expand on that subject. Manufacturing plants, utilities and chemical process facilities are asset-intensive organizations that depend on superior management of physical assets. Some owners may confuse capital asset replacement…

Read More