Rotating Equipment Repair

Predictive Maintenance of Rotating Equipment

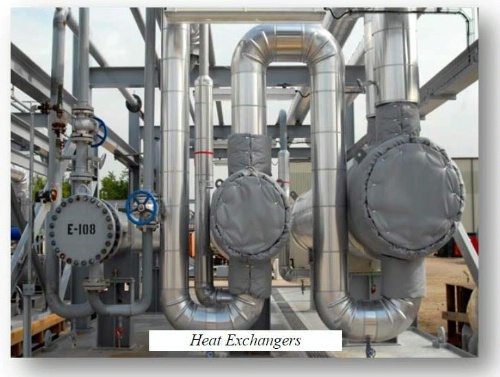

From food manufacturers to chemical plants, a typical industrial plant may have dozens to hundreds of pieces of rotating equipment. These include pumps, motors, gearboxes, turbines, fans, and more. Many of these pieces of equipment are crucial to the operation of the plant, and even non-essential assets have an important purpose to serve. When one…

Read MoreCan Effective Preventive Maintenance Scheduling Reduce Downtime?

Industries often operate 24 hours per day to maximize production, which causes them to push machines to their limits. The rate of machine part failure is also increasing as a result. Demand has increased for preventive maintenance (PM), but it requires complex coordination with production, maintenance, and management departments. Below we will discuss the separation…

Read More4 Maintenance Tips to Extend Equipment Life and ROI

Heavy machinery, especially in oil and gas, mining, farming, or other industrial applications, requires regular maintenance to ensure they continue working reliably. When large machinery is poorly maintained, it not only runs inefficiently, but is also more likely to breakdown and cost you thousands – not to mention that faulty equipment can pose a serious…

Read MoreMisalignment of the Pump Shaft – One of the Top Six Pump Vibration Problems

If your plant is being stretched to its financial limit, you may be looking for ways to simplify some of your processes and procedures. Replacement of underperforming equipment and other costly solutions aren’t always the answer, and sometimes going back to basics can be all you need. For instance, trouble-shooting the root cause of a…

Read MoreBent Pump Shafts – One of the Top Six Pump Vibration Problems

As part of our series on the top 6 pump vibration problems, we would like to focus on bent pump shafts. A bent pump shaft can occur as the result of damage during operation, rigging, improper configuration, or even shipping. There are straightening methods that can be properly applied to salvage damaged pump shafting, although…

Read MorePump Flow Pulsation – One of the Top Six Pump Vibration Problems

Previously, we discussed the top 6 vibration problems that cause pumps to underperform or fail altogether. In this entry, we will discuss the issue of pump flow pulsation. Pulsation is the result of uncontrolled pressure waves caused by a change in flow. Media in a pump has a mass and there are required acceleration forces…

Read MoreCavitation – One of the Top Six Pump Vibration Problems

Previously we discussed the top 6 pump vibration problems, with cavitation as the most prevalent. Now it seems appropriate to discuss cavitation further including its causes and prevention methods. In short, pump cavitation is the formation of cavities or bubbles in the pumped media that develop in areas of low pressure around the impeller. When…

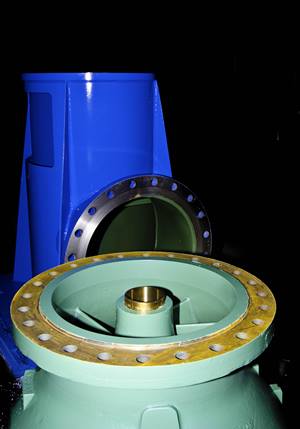

Read MorePump Impeller Imbalance – One of the Top Six Pump Vibration Problems

We have previously shared the top 6 vibration problems that lead to inferior pump performance. In this article we’ll discuss one of the more difficult ones: pump impeller imbalance. A number of factors can cause a pump’s impeller or other components to become imbalanced including improper use, collision with other equipment, and even normal wear…

Read MoreTop Six Pump Vibration Problems

Houston Dynamic Service’s technicians are dedicated to quality and trained in the latest rotating equipment repair techniques. Given our combined years of experience, we have seen the range of things that can go wrong in a large variety of pumps. We would like to share some of the knowledge that is gained through that experience.…

Read MoreRepair Sundyne Pump Diffuser Instead of Replacing

Houston Dynamic Service has extensive experience repairing Sundyne pumps and compressors. Our goal is to provide repairs that are more cost effective than replacing equipment, with a guarantee that the lead time will be significantly less than you would typically experience when replacing equipment or even critical components. Why replace equipment or costly components? HDS…

Read More