Posts by Houston Dynamic

Misalignment of the Pump Shaft – One of the Top Six Pump Vibration Problems

If your plant is being stretched to its financial limit, you may be looking for ways to simplify some of your processes and procedures. Replacement of underperforming equipment and other costly solutions aren’t always the answer, and sometimes going back to basics can be all you need. For instance, trouble-shooting the root cause of a…

Read MoreBent Pump Shafts – One of the Top Six Pump Vibration Problems

As part of our series on the top 6 pump vibration problems, we would like to focus on bent pump shafts. A bent pump shaft can occur as the result of damage during operation, rigging, improper configuration, or even shipping. There are straightening methods that can be properly applied to salvage damaged pump shafting, although…

Read MorePump Flow Pulsation – One of the Top Six Pump Vibration Problems

Previously, we discussed the top 6 vibration problems that cause pumps to underperform or fail altogether. In this entry, we will discuss the issue of pump flow pulsation. Pulsation is the result of uncontrolled pressure waves caused by a change in flow. Media in a pump has a mass and there are required acceleration forces…

Read MoreCavitation – One of the Top Six Pump Vibration Problems

Previously we discussed the top 6 pump vibration problems, with cavitation as the most prevalent. Now it seems appropriate to discuss cavitation further including its causes and prevention methods. In short, pump cavitation is the formation of cavities or bubbles in the pumped media that develop in areas of low pressure around the impeller. When…

Read MorePump Impeller Imbalance – One of the Top Six Pump Vibration Problems

We have previously shared the top 6 vibration problems that lead to inferior pump performance. In this article we’ll discuss one of the more difficult ones: pump impeller imbalance. A number of factors can cause a pump’s impeller or other components to become imbalanced including improper use, collision with other equipment, and even normal wear…

Read MoreTop Six Pump Vibration Problems

Houston Dynamic Service’s technicians are dedicated to quality and trained in the latest rotating equipment repair techniques. Given our combined years of experience, we have seen the range of things that can go wrong in a large variety of pumps. We would like to share some of the knowledge that is gained through that experience.…

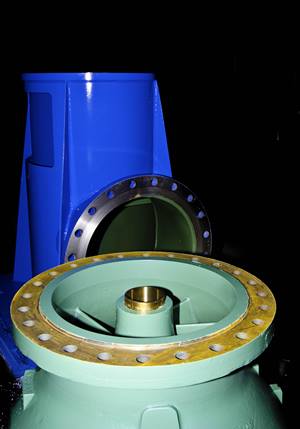

Read MoreRepair Sundyne Pump Diffuser Instead of Replacing

Houston Dynamic Service has extensive experience repairing Sundyne pumps and compressors. Our goal is to provide repairs that are more cost effective than replacing equipment, with a guarantee that the lead time will be significantly less than you would typically experience when replacing equipment or even critical components. Why replace equipment or costly components? HDS…

Read MoreExtend Seal Life with Sundyne Seal Failure Analysis from HDS

Houston Dynamic has the expertise and inventory to repair or rebuild Sundyne pumps and compressors, and the job is guaranteed to cost less than exchanging key parts for refurbished parts. You can also be assured of shorter lead times and no expedite charges. We understand the frustration our customers experience when they have a pump…

Read MoreHouston Dynamic Now Offering Sundyne Equipment Repairs and Parts

HDS has over 40 years of experience in all types of rotating equipment repairs. But when a Sundyne pump was brought in for repairs recently, it presented new challenge even for their experienced staff. Sundynes are typically repaired by the OEM or their exclusive distributors, so not many independent repair shops have significant experience with…

Read MoreThe importance of proper alignment in rotating equipment performance

As with all machinery and equipment, the mantra is “Maintenance, maintenance, and more maintenance!” For your equipment to keep running at peak performance, you must keep it properly lubricated and aligned. The importance of proper alignment in your rotating equipment’s performance cannot be stressed enough. When the belts or shafts of your equipment are misaligned,…

Read More