Posts by Houston Dynamic

Maximizing Operational Efficiency: The Case for Energy-Efficient Capital Equipment

As energy costs continue to rise, industrial companies are under increasing pressure to reduce their consumption and lower operational costs. Energy efficiency isn’t just a buzzword—it’s a critical factor in achieving sustainable operations, enhancing profitability, and complying with evolving regulations. For maintenance managers, engineers, plant managers, and other personnel overseeing capital equipment like industrial pumps,…

Read MoreTop 5 Rotating Equipment Safety Best Practices for Reliability and Maintenance Management

Rotating equipment plays a fundamental role in industrial operations, powering everything from pumps and compressors to turbines and conveyors. However, with its critical function comes significant safety risks. The U.S. Bureau of Labor Statistics (BLS) reports that machinery-related accidents account for nearly 15% of all workplace fatalities in manufacturing and industrial settings. The key to…

Read MoreThe Role of Proper Lubrication in Rotating Equipment Performance

Is your rotating equipment experiencing frequent overheating, unusual noises, or unexpected shutdowns? Perhaps you’ve noticed smearing, discoloration, or other warning signs of mechanical distress. These symptoms often point to inadequate lubrication—a common but preventable issue in the maintenance of rotating machinery. Ensuring proper lubrication is critical for maximizing equipment reliability and minimizing downtime. Why Lubrication…

Read MoreThe Critical Role of Alignment in Turbine Preventive Maintenance

Alignment is one of the most critical, yet often overlooked, aspects of turbine maintenance. For Maintenance Managers, Maintenance Engineers, and Plant Managers, ensuring proper alignment is vital for the longevity, efficiency, and reliability of turbine systems. Misalignment can lead to catastrophic failures, increased downtime, and significantly higher repair costs. In this article, we will explore…

Read MoreSix Essential Strategies for Enhancing Equipment Reliability

Critical rotating equipment represents some of the most significant investments within any manufacturing organization. The performance and reliability of this machinery are pivotal for ensuring product quality and operational efficiency. For that reason, optimizing equipment reliability is crucial for maintaining smooth operations and minimizing disruptions. 1. Prioritize Operator Training Investing in comprehensive operator training is…

Read MoreMaximize Equipment Reliability with Condition Monitoring

Your equipment was expensive to design, purchase, and install. This does not include the costs to operate, maintain, diagnose, repair, and ultimately replace. But did you know you can maximize equipment reliability with condition monitoring? We will show you how below. Do I Need Condition Monitoring? Depending on your operation, your rotating equipment could be…

Read More3 More Tips for Implementing a Predictive Maintenance Program

We have previously written about Tips for Implementing a Predictive Maintenance Program and want to go a little deeper. Prioritizing your assets, identifying key performance indicators, and utilizing the best tech are anll great ideas. But we have more below. Focus on Staff Training and Management of Changes It is essential that all necessary owners,…

Read More3 Tips for Implementing a Predictive Maintenance Program

HDS is a huge fan of proper maintenance, with a focus on predictive rather than reactive maintenance. This approach comes with many benefits in both reduced down time and more efficient uses of maintenance resources. Below we will share 3 expert tips for implementing a predictive maintenance program. Prioritize Your Assets The first part to…

Read MoreStrategies to Reduce Cavitation in Centrifugal Pumps

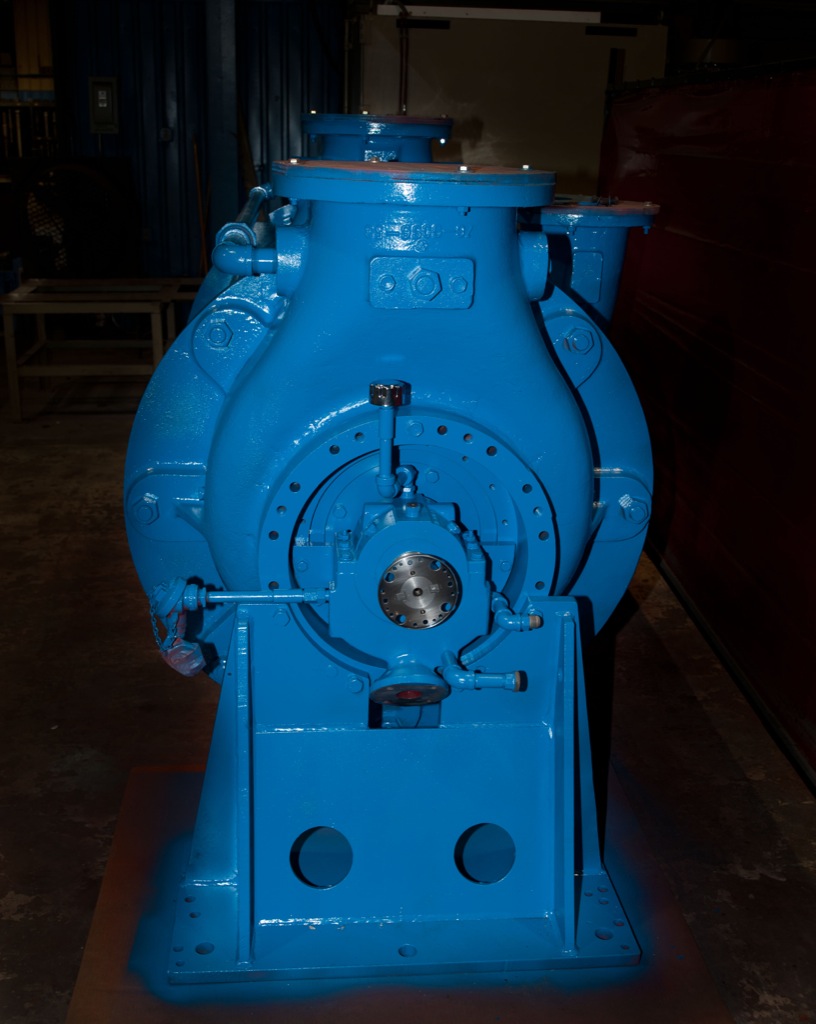

The team at Houston Dynamic Supply have seen all sorts of issues with rotating equipment, including centrifugal pumps. One of the most common and devastating is cavitation. This happens when vapor bubbles form in low-pressure pockets and implode when entering into higher pressure areas. It leads to all sorts of damage on pump internals and…

Read MoreUpgrade Legacy Pumps With Modern Materials and the Latest Technology

New and legacy pumps are an essential part of many facilities such as water for municipalities, oil and gas, power generation, manufacturing, and many others. In the end, all pumps eventually succumb to wear, corrosion, and slowdowns or breakdowns. It is critical to have a plan in place for repairs and replacements, but there is…

Read More