Rotating Equipment Repair

Houston Dynamic Service Today

While there have been many bumps in the road over the years, since December 2001 Houston Dynamic Service has adopted a quality culture and approach to completing projects that has put them in position as one of the largest independent rotating equipment repair shop in Houston. “Growth and success in this business requires state-of-the-art repair…

Read MoreOur ISO 9001 Journey: Compliant – at Last!

During the final phase of our ISO 9001 project, we continued to focus on implementation of various requirements of the ISO 9001: 2008 standard. There were a number of verifications performed to ensure that our QMS met all specified requirements. On-Going Implementation Some implementation activities take longer to complete, so we had to carry…

Read MoreOur ISO 9001 Journey: Putting our Documentation to the Test: Implementation

The first step in our preparation for ISO 9001 compliance was the arduous process of documenting all of the essential procedures used within our business. That was only the beginning! After everything had been documented, we began an implementation phase which put our documented procedures to the test. Step 1 during implementation was to provide…

Read MoreOur ISO 9001 Journey: Documentation is Essential

Documenting all of the procedures required in order to comply with ISO 9001 requirements is an essential part of the process. The quality management system (QMS) documentation is at the core of any ISO 9001 certification, and is the first phase of the work required to gain compliance. There are two main criteria regarding the…

Read MoreHDS is Serious About Quality!

HDS just completed the next evolution in our quest to consistently provide the highest quality rotating equipment repairs in the industry. We’ve always said what sets us apart is our dedication to the customer and willingness to exceed their expectations. After a great deal of focus and commitment from our employees, especially Luke Lau and…

Read MoreYou Have a BIG Pump that needs repair?

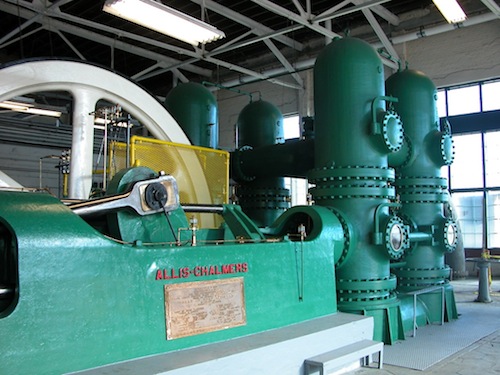

This is the first of two river pumps HDS is repairing in our shops. The overall length of this pump is 37-1/2′ and 29,000 pounds. All rotating equipment is disassembled and goes through inspection and analysis. Once our engineers have determined the best course of action to restore your pump to your specifications, your project…

Read MoreHouston Dynamic Service Facilty Tour

Houston Dynamic Service (HDS) was founded in 1976, and is located in Houston, Texas. In 2001, our current President, Clayton Lau, purchased HDS from its previous owner. Because we are an independent aftermarket rotating equipment repair facility, we have the flexibility to not only move quickly, but also to provide customized solutions to your toughest…

Read MoreAnother Great Day In The HDS Shop!

Here are some of the pump projects we’re working on today. Call us if you want us working on YOUR equipment repair or overhaul project tomorrow! Complete overhaul of a vertical, multi-stage pump for a major petrochemical complex: View 1 Complete overhaul of a vertical, multi-stage pump for a major petrochemical complex – View 2…

Read MoreVital Items to Check on a Centrifugal Pump After Disassembly

After taking delivery of a pump in our shop for repair, our general protocol is to disassemble the pump, and then carefully inspect for primary types of wear and tear. This is done prior to the pump being blasted and run through NDT (Non-Destructive Testing) in order to identify potential issues that could be causing…

Read MoreQuality Control Department a Repair Shop Priority

“I’ve just always liked a new challenge,” says Bobby Martinez, Quality Control Manager with Houston Dynamic Services. fter working more than 33+ years in the pump shop and machine pump industry – 3 of those years at HDS – the company offered Bobby a new opportunity. “I have experience with the entire process from creating…

Read More