Training Houston’s Next Generation of Skilled Manufacturing Workers

American manufacturing faces a workforce crisis that threatens production capacity and economic stability.

Houston Dynamic Service has addressed this challenge for over a decade through mentorship-based training that develops skilled technicians from the ground up. Since 2013, our veteran-owned company has proven that investing in people—not just complaining about labor shortages—builds sustainable solutions.

This article outlines the national manufacturing skills crisis, explains why traditional hiring fails, and shows how mentorship-based apprenticeship programs create the skilled workforce that Houston’s industrial economy depends on.

The Manufacturing Skills Shortage Crisis

Nearly 450,000 Skilled Labor Jobs Remain Unfilled in the US in 2026

The manufacturing sector confronts a severe talent gap that continues to widen. According to the Manufacturing Institute and Deloitte, more than 65 percent of manufacturing companies identify recruiting and retaining workers as their number one business challenge. The industry will need 3.8 million additional workers by 2033, with projections showing that 1.9 million of these positions could remain unfilled if workforce challenges are not addressed.

As of early 2025, approximately 449,000 manufacturing jobs remain open across the United States. This shortage directly impacts production capacity, equipment maintenance schedules, and operational reliability in critical industries including energy, petrochemical processing, and industrial manufacturing.

Specialized Skills Require Extended Training

Manufacturing roles demand technical expertise that cannot be acquired quickly. Carolyn Lee, president and executive director of the Manufacturing Institute, explains that the most difficult skills to find involve maintaining and repairing equipment. Every manufacturer seeks technicians with these capabilities, but these skills require one to two years of initial training followed by another one to two years of contextualization within a specific plant environment.

Perception Gaps Deter New Workers

Many Americans hold outdated views of manufacturing work, perceiving it as dirty, repetitive, and low-tech. Modern manufacturing facilities operate with advanced precision equipment, computerized systems, and clean environments. This perception disconnect prevents potential workers from considering manufacturing careers despite competitive compensation and advancement opportunities.

Real-world example: A recent graduate might choose a $45,000 office job over a $60,000 machining position simply because they’ve never been exposed to modern manufacturing environments or understood the career advancement potential in skilled trades.

Aging Workforce Without Succession Planning

Retirements create knowledge gaps that many companies struggle to fill. Decades of hands-on expertise walk out the door when experienced machinists and technicians retire without having trained successors.

What companies often miss:

Waiting until workers retire to address succession planning means losing the opportunity for knowledge transfer—the tacit expertise that can only be passed through years of working side-by-side.

Houston’s Position in the Manufacturing Workforce Crisis

Houston serves as a critical manufacturing hub for the energy sector, with concentrated demand for rotating equipment repair and precision machining services. The city’s industrial base includes refining, petrochemical processing, power generation, and offshore production operations. These industries depend on continuous operation of turbomachinery, pumps, compressors, and related equipment.

Local manufacturing employers face the same recruiting challenges seen nationally, intensified by Houston’s specialized industrial requirements. Equipment failures in energy facilities can cost hundreds of thousands of dollars per day in lost production, making skilled maintenance technicians essential to operational continuity.

Real-world example: A delayed turbine repair due to technician shortage can idle an entire production unit, costing a Gulf Coast refinery $250,000+ per day in lost capacity—making the ROI on workforce development programs immediately clear.

How Houston Dynamic Service Develops Skilled Labor

Since 2013, Houston Dynamic Service has operated a mentorship-based training program that addresses the skills shortage through direct action rather than complaint. The veteran-owned company recognized that waiting for qualified candidates to appear would not solve the problem.

Mentorship-Based Apprenticeship Model

Houston Dynamic Service’s approach centers on pairing inexperienced workers with master machinists and technicians. Clayton Lau, company leadership, explains the philosophy:

“Since we require a highly skilled labor force, we implemented a program where we develop young people who are willing to learn these skills. We understand it will take them 2–4 years to get there, and we are teaching them from the ground up. We assign people to a mentor who trains them in the shop, and it is filling the void of skilled labor in the shop, and will enable us to carry on our tradition of skill and quality.”

Clayton Lau – PrESIDENT, Houston Dynamic

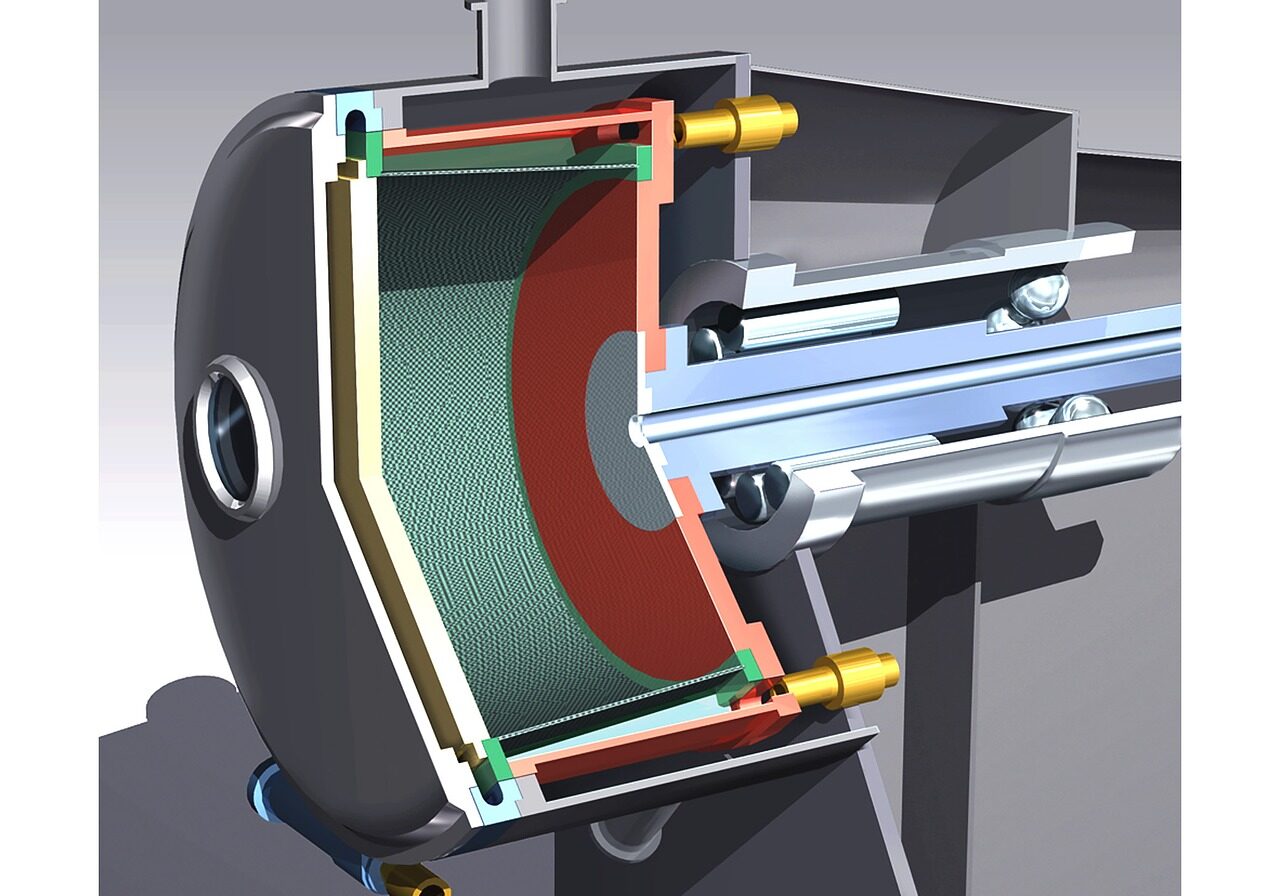

This hands-on training occurs within Houston Dynamic Service’s ISO 9001-certified facility, where trainees work on actual customer equipment under experienced supervision. The program emphasizes precision machining, equipment diagnostics, repair techniques, and quality standards that meet industry specifications.

What Trainees Learn Over 2-4 Years of Skilled Labor Training for Rotating Equipment

Years 2-3: Specialized Equipment Knowledge

Equipment disassembly and inspection techniques teach trainees to identify wear patterns, failure modes, and root causes of equipment problems. Machining operations include lathe work, milling, drilling, grinding, and other material removal processes on turbines, pumps, compressors, and gearboxes.

Years 3-4: Independent Problem-Solving

Assembly procedures and clearance specifications ensure that rebuilt equipment meets original equipment manufacturer standards. Trainees learn proper bearing installation, shaft alignment, seal clearances, and torque specifications. Quality documentation and traceability requirements familiarize trainees with ISO 9001 quality systems.

What traditional approaches miss:

The assumption that skilled workers can be hired “ready-made” ignores the reality that equipment-specific expertise and company quality standards require contextualized learning that only happens through extended mentorship.

Interested in precision machining careers?

Why Mentorship Works Better Than Classroom Training

Mentorship proves particularly effective for skilled trades because much of the knowledge cannot be taught through classroom instruction alone.

Tacit Knowledge Transfer

Experienced machinists possess intuitive understanding developed through years of practice. They recognize subtle vibrations, interpret wear patterns, and anticipate problems before they occur. This tacit knowledge transfers through observation, practice, and guided experience rather than textbook study.

Real-world example: An experienced machinist can feel when a bearing seat is machined to the correct tolerance by the sound and resistance of the cutting tool—a skill that takes hundreds of hours of supervised practice to develop, not something that can be taught in a classroom.

Real Equipment, Real Consequences

Training on actual customer equipment creates appropriate gravity and attention to detail. Trainees understand that their work directly impacts facility operations and safety. This context accelerates learning and instills quality-focused work habits from day one.

Continuous Feedback and Correction

Mentors provide immediate correction when trainees make errors, preventing bad habits from forming. They demonstrate correct techniques, explain the reasoning behind procedures, and gradually increase trainee independence as competence develops.

Economic Impact of Apprenticeship Programs

Research on structured apprenticeship programs demonstrates their economic value beyond individual companies.

Proven ROI on Skills Training

A Brookings Institution and Opportunity America study found that FAME program graduates earned nearly $98,000 five years after completion, compared to roughly $52,783 for non-participants. This $45,000 annual earnings difference demonstrates the financial return on skills training investment.

These programs succeed because they combine paid work experience with targeted instruction, eliminating student debt while building practical competence. Graduates enter the workforce with proven skills and established employment relationships.

Community Economic Stability

Local training programs create career pathways for Houston-area residents without requiring college degrees. Skilled manufacturing positions offer competitive wages, benefits, and advancement opportunities that support family economic stability.

Knowledge Retention Within Organizations

Internally trained technicians understand company procedures, quality standards, and customer requirements from the beginning of their careers. They build institutional knowledge rather than bringing external practices that may not align with company values.

What More Companies Should Consider

The Manufacturing Institute emphasizes that locally and regionally led public-private partnerships produce the best workforce development outcomes. Manufacturers who engage with community colleges and training providers create the talent pipelines they need rather than competing for scarce existing talent.

Houston Dynamic Service’s approach demonstrates that individual companies can make meaningful impact without formal partnerships. The key requirements are commitment to multi-year development timelines and assignment of experienced personnel as mentors.

Practical Steps for Starting a Mentorship Program

Companies interested in developing similar programs can start with modest commitments:

- Identify one or two experienced technicians willing to mentor — Not all skilled workers have teaching aptitude, so selecting mentors carefully matters

- Hire trainees with good work ethic and aptitude — Willingness to learn and attention to detail predict training success better than prior experience

- Set realistic 2-4 year timelines — Expecting immediate productivity undermines both trainee development and mentor effectiveness

- Document training progression — Clear milestones and competency checkpoints help both trainees and mentors track development

- Compensate trainees fairly as skills develop — Progressive wage increases tied to demonstrated competency encourage continued development

The Veteran-Owned Perspective on Training

Houston Dynamic Service’s veteran-owned status influences its approach to workforce development. Military training emphasizes hands-on learning, mentorship, and progressive skill building. These principles translate naturally to industrial apprenticeship programs.

The commitment to developing people from the ground up reflects values of service, investment in others, and long-term thinking. These values position training programs as community contributions rather than purely business transactions.

Final Takeaway

The manufacturing skills shortage will not resolve through traditional hiring approaches. Companies that wait for qualified candidates to appear will continue facing recruitment challenges. Those that invest in developing talent from the ground up build sustainable workforce solutions.

Houston Dynamic Service’s twelve-year commitment to mentorship-based training demonstrates that individual companies can make meaningful impact. The program has filled internal skill gaps while contributing to Houston’s broader manufacturing talent base.

For an industry facing 1.9 million projected unfilled positions, this approach offers a practical path forward. Mentorship-based training transforms willing learners into skilled technicians, ensures knowledge transfer from retiring workers, and builds the foundation for continued manufacturing success.

When companies invest in people—teaching from the ground up with realistic timelines and experienced mentors—they don’t just fill positions. They build the expertise that keeps Houston’s industrial economy running.

Interested in partnering on workforce development or need rotating equipment repair services?

Houston Dynamic Service provides precision machining, comprehensive repairs, and ongoing service for pumps, compressors, turbines, and gearboxes. Contact us at 713-636-5587 or request service online.

Frequently Asked Questions: Houston Skilled Labor Career Training

Training a skilled machinist requires two to four years of hands-on experience under mentor supervision. The first year covers fundamental operations and safety practices, while years two through four build specialized knowledge in equipment types and advanced repair techniques. This timeline allows trainees to develop both technical skills and the judgment needed for independent problem-solving.

Manufacturers struggle to find qualified workers because specialized skills require one to two years of training plus another one to two years of contextualization within specific plant environments. According to the Manufacturing Institute, there are no workers readily available with these skills, and most companies have not invested in developing their own training programs. The aging workforce compounds this problem as experienced technicians retire without having trained successors.

Rotating equipment technicians need precision measurement skills, equipment diagnostic capabilities, machining operation expertise, and knowledge of assembly procedures and clearance specifications. They must understand bearing installation, shaft alignment, seal clearances, and torque specifications while maintaining quality documentation that meets ISO standards. These skills are developed through extended hands-on practice rather than classroom instruction alone.

Yes. Mentorship proves more effective for manufacturing skills because much of the required knowledge cannot be taught through classroom instruction. Experienced machinists possess intuitive understanding developed through years of practice that transfers through observation and guided experience. Training on actual customer equipment creates appropriate attention to detail and allows for immediate feedback and correction.

Houston serves as a critical manufacturing hub for the energy sector with concentrated demand for rotating equipment repair and precision machining services. The city’s industrial base includes refining, petrochemical processing, power generation, and offshore production operations. This concentration creates both demand for skilled workers and economic justification for training investments, as the skills required command premium compensation.

Apprenticeship programs reduce dependence on tight external labor markets and build workforce stability. Companies that develop internal talent gain employees who understand company procedures, quality standards, and customer requirements from the beginning of their careers. Research shows that structured apprenticeship graduates can earn nearly $98,000 five years after completion, demonstrating that investments in training produce workers with valuable, scarce skills.

Companies should hire trainees with strong work ethic and aptitude for technical work rather than seeking fully formed skills. Willingness to learn and attention to detail predict training success better than prior experience. Not everyone has the temperament for precision work, so selecting candidates who demonstrate patience, careful observation, and genuine interest in how things work increases program success rates.