Main Pump Types – Reciprocating Piston

In continuing with our series, Pumps 101, we are going to focus this entry on reciprocating piston pumps. Many pumps fall into the positive displacement arena, and they can generally be divided into two categories: reciprocating and rotary. Reciprocating pumps operate with the use of plungers, diaphragms, or pistons. Rotary pumps tend to use rotating parts. The chamber in reciprocating pumps that holds the liquid is usually stationary.

Reciprocating Piston Pump Basics

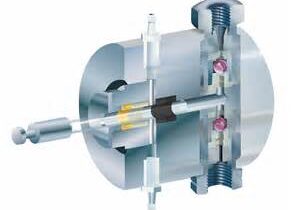

A reciprocating pump uses the motion of a piston in a cylinder to move media and allow for only inwards and outwards movement of the pumping media. The cylinder has an inlet and outlet valve. The piston is often connected to a crankshaft and has a liner made of ceramic or synthetic material to provide proper sealing between moving parts.

Benefits of Reciprocating Piston Pumps

Reciprocating piston pumps move media within a very tight tolerance cylinder. Due to this mechanical design, these pumps produce high discharge pressures. As a result, these pumps can be used to move liquids and even compress gases. The pumps can also operate with no need to fill the cylinders before hand, or “self-priming.” With regular and proper maintenance, reciprocating piston pumps can operate reliably for decades.

However, reciprocating piston pumps are not recommended to move viscous liquids or for applications that require low volume rates of flow.

Types of Reciprocating Piston Pumps

- Single Reciprocating Piston Pump– The pump operates by having a single acting cylinder move media, similar to a bicycle pump. Media is discharged from one side of the cylinder by a stroke of the piston.

- Double ReciprocatingPiston Pump – This pump operates by moving media in the first half of the cycle from one side of the pump and then to another in the second half of the cycle. As media is moved, it is often discharged in a more smooth and higher amount compared to the single piston pump.

- Lift pump – These pumps use an upstroke of the piston to draw in media through a valve and into the piston assembly. The media is then moved through the pump with more strokes.

- Axial Piston Pump– These are found in many cars and air conditioning units, and use a number of pistons in a block to move media.

Reciprocating piston pumps can also be duplex with two piston and cylinder assemblies or triplex piston pumps with three assemblies. They can also be modified for different industries and different applications.

Conclusion on Reciprocating Piston Pumps

Although they can be costly, reciprocating piston pumps are among the most efficient pumps. They have a pressure rating as high as 10,000 psi. This makes them an ideal choice for many high-pressure applications, such as hydraulic oil pumping. However, their design can also allow for a high level of contamination.

At Houston Dynamic Service, we have the most skilled pump maintenance professionals in the industry. They are experienced in providing high quality maintenance and repair services for all types of pumps, compressors, turbines, gear boxes, and other equipment. To learn more, contact us to discuss how we can partner with you to keep your pumps running more efficiently with less down time.

Share this post: