Main Pump Types – Displacement

We have previously discussed the basics of pumps including power, classification, and more. In continuing with the series, we are going to focus on one of the most commonly used types of pumps, the displacement pump. As they are the most popular, the focus will be on positive displacement pumps. These types of pumps are commonly used throughout various industries because they produce regulated flow, no matter what the pressure.

Displacement Pump Basics

Displacement pumps operate by periodically adding energy through force to one or more movable boundaries. The result is increased pressure moving media through valves to the discharge. Also known as constant flow machines, displacement pumps produce a constant flow but in most cases use a safety or relief valve. These valves are usually set to activate should the pump reach a certain level, to prevent leaking and other hazards.

Displacement Pump Uses

Given their nature, displacements pumps are often used for applications where viscous liquids or liquids that contain fragile or suspended solids, are moved. While a centrifugal pump has a higher flow rate, displacement pumps produce higher pressures needed for many applications. These include:

- High viscosity – even a little viscosity can affect the flow rate in a pump

- Pressure variations – same as above

- High pressure – displacement pumps can produce pressures of anywhere from 250 psi to 3,000 psi, depending on the pump

- Sensitive liquids – the low speeds at which displacements pumps operate is ideal for this media

- Suction lift – because displacements pumps create a vacuum on their inlet, they can create a suction lift

- Continued processes – displacement pumps can move media without the need for larger motors and more energy

Classification of Displacement Pumps

Displacement pumps are often divided into reciprocating and rotary types, depending on the application.

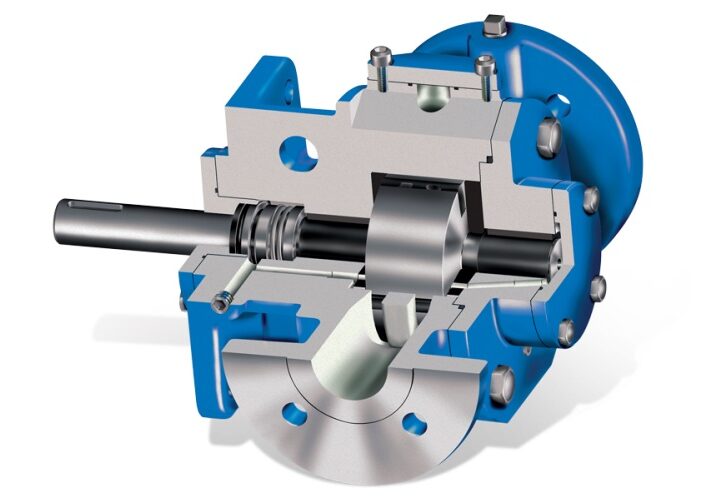

Rotary displacement pumps – They operate using rotating parts to move liquid through the pump and out. They are not recommended for large solids or abrasive fluids that can wear out these parts.

Reciprocating displacement pumps – They operate by using a repetitive mechanism that expands and contracts to move media. They also use one or more check valves at the inlet and outlet to prevent reverse flow. They are best for applications in which reverse flow would be hazardous, such as in the water or chemical industries.

These pumps can also further be divided into many sub-categories including but not limited to:

Rotary:

- Gear pumps – as implied by the name, they use rotating gears to move fluids. This configuration is ideal for high viscosity liquids, hydraulic power, and even applications where the liquid needs to be “squeezed” together.

- Screw pumps – they move liquids by turning a screw within the pump. There can be one or multiple screws, and they are often used in offshore and marine applications.

- Progressive cavity pumps – The pump uses a rotating mechanism to move media through its various chambers. This makes them ideal for processes such as moving viscous and shear-sensitive media.

Reciprocating:

- Diaphragm pumps – they use a flexing mechanism to move fluid in and out of the pump. They also use check valves to keep fluid from flowing out the inlet.

- Piston pumps – they operate in a similar manner to a passenger vehicle’s pistons. They use an energy source to move the piston up and down and get media through the pump. They can even move gases effectively.

- Plunger pumps – similar to the above, this pump uses a plunging mechanism to move fluid and is generally used to move high solids, such as in the sewage industry.

Displacement pumps can be either ASME or API approved. When chosen correctly and used in correct configurations, the pumps produce a reliable and efficient system. Choosing from among the numerous material, size, hydraulic, and other factors are a critical part of choosing the correct configuration and can sometimes be overwhelming.

At Houston Dynamic Service, we have the most skilled pump technicians in the industry. They are experienced in providing high quality maintenance and repair for many types of rotating equipment, including pumps. Contact us today to discuss how we can partner with you to keep your pumps running efficiently and with minimal interruption to production.

Share this post: