Houston Dynamic Service Today

While there have been many bumps in the road over the years, since December 2001 Houston Dynamic Service has adopted a quality culture and approach to completing projects that has put them in position as one of the largest independent rotating equipment repair shop in Houston.

Some stats on the Houston repair facility:

- 35,000 sq ft of facility space under crane

- 20 ton lift capacity

- Max lathe capacity – 30’x72” swing

- Vertical max capacity is 105”

- Horizontal milling capacity is a 5” spindle

As for the need for skilled technicians, HDS created a Mentorship/Apprenticeship Program in order to train and develop from within.

“Since we require a highly skilled labor force, we implemented a program where we develop young people who are willing to learn these skills. We understand it will take them 2-4 years to get there, and we are teaching them from the ground up. We assign people to a mentor who trains them in the shop, and it is filling the void of skilled labor in the shop, and will enable us to carry on our tradition of skill and quality,” says Lau.

As a result of having state-of-the-art facilities and a skilled labor force, HDS has been able to complete large-scale equipment repair projects that really set the bar for the industry:

- Complete revamp of all the pumps for a “moth ball” power plant in Corpus Christi. The project took over a year. HDS repaired two large vertical pumps that had been idle for over a year, met all deadlines while working in conjunction with the customer’s engineers, as well as outside engineering contractors.

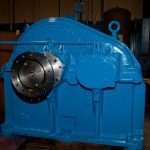

- Complete system rebuild for a power plant in Tennessee. This was a very large project that involved the rebuilt of 4 CENTRI-STAK compressors and 2 gear boxes.

While there are a lot of good rotating equipment repair shops out there, HDS delivers a level of care and quality and the physical capacity to handle a wider diversity of jobs. HDS technicians know what is required to get jobs done quickly and correctly to meet the service and quality requirements of our customer base.

“We are very grateful for the level of success we have achieved in the Houston Gulf Coast region over the last 35 years, and look forward to expanding across the United States,” says Lau.

Share this post: