A Pump Primer

Pumps are only one of the types of rotating equipment we service here at HDS; but we thought it would be a good idea to go over the various types of pumps we repair on a daily basis.

Positive displacement, or reciprocating, pumps are highly efficient pumps that can be designed to pump any type of fluid – mud, concrete, oil, water, and more. They are not affected by changes in pressure and provide a constant flow of non-solids. There are six types of positive displacement pumps: piston pumps, screw pumps, diaphragm pumps, peristaltic pumps, and gear pumps. Each are used for different purposes and in many varied industries. The type of pump of used is based on the viscosity of the liquids or non-solids that are being moved.

Piston pumps are the oldest and most basic of reciprocating pumps. They are also the most durable as they can withstand corrosive liquids, high temperatures, and be used in depths of up to 400 feet. There are two subtypes of piston pump – the radial piston pump and the axial piston pump. A radial piston pump is actually a type of hydraulic pump that is preferred to transport hydraulic fluids like mineral oil, synthetic esters, and coolants. They are used in test rigs, transmissions, and liquid fertilizer injectors. They are extremely reliable, make little noise, and great for high-pressure operations. An axial piston pump is a cylinder with an odd number of pistons moving up and down, commonly found in pressure washers and aircraft. They can have problems with remaining lubricated and issues with leakage. Although they have certain design flaws, they are relatively inexpensive and simple to operate.

Piston pumps are the oldest and most basic of reciprocating pumps. They are also the most durable as they can withstand corrosive liquids, high temperatures, and be used in depths of up to 400 feet. There are two subtypes of piston pump – the radial piston pump and the axial piston pump. A radial piston pump is actually a type of hydraulic pump that is preferred to transport hydraulic fluids like mineral oil, synthetic esters, and coolants. They are used in test rigs, transmissions, and liquid fertilizer injectors. They are extremely reliable, make little noise, and great for high-pressure operations. An axial piston pump is a cylinder with an odd number of pistons moving up and down, commonly found in pressure washers and aircraft. They can have problems with remaining lubricated and issues with leakage. Although they have certain design flaws, they are relatively inexpensive and simple to operate.

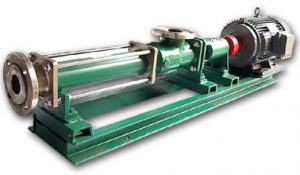

The second type of reciprocating pump, the screw pump, is probably one of the most common types of positive displacement pumps available. In its most basic form, it is a single screw that transports material along the screw’s spindle. This particular sub-type is used for applications such as irrigation, transporting grains, and in sewage treatment plants. There are twin screw rotary forms of screw pumps that are two spindles rotating along dual chambered shafts. These versatile pumps used in industries where fluids can be thin or viscous, such as the chemical and cosmetic industries. Triple screw rotary pumps use three high-pressure spindles to force liquids into closed chambers. They are typically found in the petroleum industry because they can be used to pump highly viscous fluids.

The second type of reciprocating pump, the screw pump, is probably one of the most common types of positive displacement pumps available. In its most basic form, it is a single screw that transports material along the screw’s spindle. This particular sub-type is used for applications such as irrigation, transporting grains, and in sewage treatment plants. There are twin screw rotary forms of screw pumps that are two spindles rotating along dual chambered shafts. These versatile pumps used in industries where fluids can be thin or viscous, such as the chemical and cosmetic industries. Triple screw rotary pumps use three high-pressure spindles to force liquids into closed chambers. They are typically found in the petroleum industry because they can be used to pump highly viscous fluids.

Diaphragm pumps use a combination of a valves and a reciprocating sheet (made of Teflon, rubber, or some type of thermoplastic) to produce a high-pressure vacuum that forces liquids into and out of a chamber. They are quiet, inexpensive, and can be used without added lubrication. Look for them in applications that involve the transportation of high-viscosity fluids, such as cements, clays, and petrochemicals.

The final type of positive displacement pump is the gear pump. Gear pumps are employed in situations where high volume and high-pressure liquids must be transported. Whereas piston pumps forcefully propel liquids with their piston action, gear pumps transport liquid by creating a vacuum with the meshing of its internal gears. They are preferred by petrochemical, marine, and laboratory applications over diaphragm pumps because of their continuous, non-pulsating flow. There are external gear pumps, internal gear, and lobe pumps. External gears use two identical spur gears to move fluids, in applications such as chemical blending, polymer metering, and in the use of corrosive liquids. Internal gear pumps use two gears that un-mesh to create a void to force fluid into the pump then re-mesh to expel the liquid. These types of gear pumps are very diverse in their applications and are found in the food, petrochemical, paper, and cosmetic industries. Rotary lobe pumps are similar to external gear pumps, but the lobes never make contact due to timing mechanisms. The pharmaceutical, food and beverage, and biomedical industries use them because of their high efficiency, durability, and sanitary qualities.

The final type of positive displacement pump is the gear pump. Gear pumps are employed in situations where high volume and high-pressure liquids must be transported. Whereas piston pumps forcefully propel liquids with their piston action, gear pumps transport liquid by creating a vacuum with the meshing of its internal gears. They are preferred by petrochemical, marine, and laboratory applications over diaphragm pumps because of their continuous, non-pulsating flow. There are external gear pumps, internal gear, and lobe pumps. External gears use two identical spur gears to move fluids, in applications such as chemical blending, polymer metering, and in the use of corrosive liquids. Internal gear pumps use two gears that un-mesh to create a void to force fluid into the pump then re-mesh to expel the liquid. These types of gear pumps are very diverse in their applications and are found in the food, petrochemical, paper, and cosmetic industries. Rotary lobe pumps are similar to external gear pumps, but the lobes never make contact due to timing mechanisms. The pharmaceutical, food and beverage, and biomedical industries use them because of their high efficiency, durability, and sanitary qualities.

No matter what types of reciprocating pumps you own, Houston Dynamic Service can provide routine maintenance and repair. We have a fully equipped pump repair shop with highly trained pump repair mechanics. We are here for you when you need us, even for emergency repairs, 24/7. With over 35 years of experience, HDS will have your equipment back up and running at peak performance in record time!

Share this post: