Leading Expert in Gear Box Repair & Rebuilds

April 21, 2014

How Proper Lubrication Can Minimize Rotating Equipment Repair

May 31, 20146 Essential Tips for Proper Rotating Equipment Preventive Maintenance

The best way to keep your rotating equipment operating properly so you can minimize repairs and downtime is to have a preventive maintenance program in place that ensures routine maintenance tasks are performed on a regularly scheduled basis. By performing pre-defined maintenance at specific intervals, you can catch potential problems early on before they become major issues and extend the time between repairs or failures.

The best way to keep your rotating equipment operating properly so you can minimize repairs and downtime is to have a preventive maintenance program in place that ensures routine maintenance tasks are performed on a regularly scheduled basis. By performing pre-defined maintenance at specific intervals, you can catch potential problems early on before they become major issues and extend the time between repairs or failures.

When creating a preventive maintenance program, there are some key things you need to focus on:

- Put safety first—When working around any moving equipment, safety is always an issue. Make sure all employees are educated on safe working practices and procedures and that everyone is working under safe, controlled conditions.

- Create a schedule and stick to it—Preventive maintenance isn’t something you do whenever you feel like getting around to it. In order for a preventive maintenance program to be truly effective, it needs to be thoughtfully planned out and scheduled. For example, your program might consist of monthly calibration checks, weekly lubrication, and even daily housekeeping.

- Don’t wait for failure—Remember, equipment breakdowns cost you time and money. The point of preventive maintenance is to be proactive and catch problems early on instead of waiting for a failure.

- Share the responsibilities—Dividing preventive maintenance tasks and responsibilities around your team gets more people involved in the process, allowing you to respond to issues more quickly and to have a better chance of detecting problems early on. It’s about working as efficiently as possible.

- Record everything—Good recordkeeping is one of the keys to good preventive maintenance. Always record the condition of the equipment being worked on, and make notes detailing the maintenance tasks performed and the date.

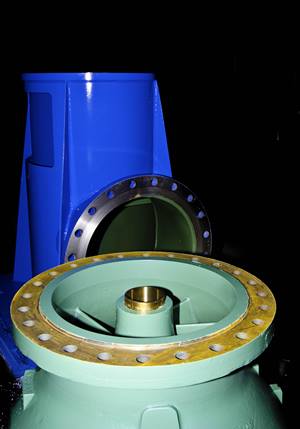

Now that you have a better idea of the guiding principles of a preventive maintenance program, it’s time to talk specifics. What should your rotating equipment preventive maintenance program include? How can you be sure you’re properly caring for your pumps, turbines, compressors, fans, blowers, gearboxes, and centrifuges?

Here are the 6 more essential tips for maintaining your rotating equipment.

- Cleaning is key to proper inspection—Regular cleaning of rotating equipment is essential to proper preventive maintenance. Not only can cleaning your rotating equipment help reduce vibration levels and improve overall performance, but it’s also necessary for thorough, accurate inspections. Simply put, cleaning off equipment lets you see any defects or problems that need to be addressed.

- Ensure proper alignment—One important aspect of smooth operation of rotating equipment is proper alignment. Properly aligned rotating equipment has reduced vibration levels, less wear and tear, lower risks of shaft fatigue and sudden failure, extended component lifetime, and reduced power consumption. Proper tools and training are essential to aligning rotating equipment correctly, so don’t skimp on this part.

- Listen for unusual sounds—When inspecting rotating equipment, such as a pump, your ears are great tools for identifying any potential issues. Listen to the equipment as it operates, and take note of any unusual sounds. Strange sounds are often warning signs that the equipment isn’t operating properly, and it’s important to try to get to the root of the problem.

- Feel for unusual vibration—High vibration levels in your rotating equipment can reduce the component life of couplings, seals, bearings, and other essential components. According to some estimates, reducing equipment vibrations levels by just 10% can increase the life of bearings by nearly 40%! One way to reduce vibration levels is to balance the rotating equipment by either using a manual balancing system (requires stoppage of equipment) or active balancing technology (can be corrected while equipment is still running).

- Keep all rotating equipment lubricated—If it moves, then it needs lubrication. Lubricating oil is absolutely vital to the health of your rotating equipment. The condition of the lubricating oil/grease should be checked on a regular basis, and relubrication should be performed as necessary at the proper levels. Proper lubrication maintenance can go a long way to preventing bearing-related repairs.

- Check all bolts—As rotating equipment runs over time, it’s possible that bolts can loosen, leading to excessive vibration and other complications. When checking your rotating equipment, always make certain the bolts are all tightened properly.

By putting these procedures in place, you can extend the lifetime of your equipment, improve its overall performance, and minimize costly repairs and downtime. Remember, preventive maintenance requires an ongoing commitment in order to be truly effective.

However, if you find yourself in a situation where despite your preventive maintenance efforts, your rotating equipment needs repair or a complete rebuild – call Houston Dynamic Service for experience you can trust, the highest quality service, and quick turnarounds.